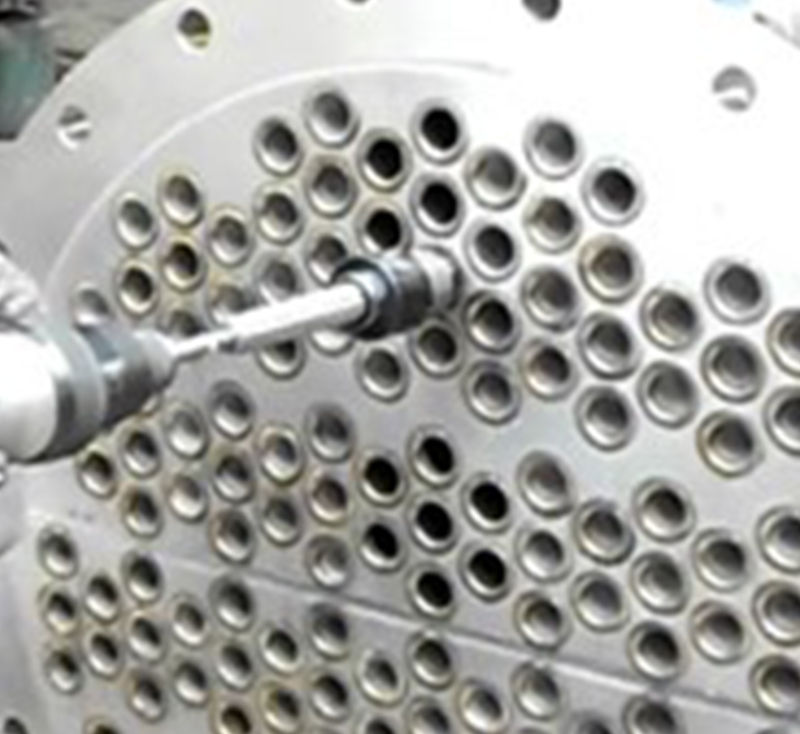

Tube Expansion & Re-Rolling

Tube expansion and re-rolling are common methods used to repair or replace damaged tubes in heat exchangers, boilers, and other industrial equipment. Tube expansion involves the use of a tube expander to enlarge the diameter of the tube, creating a tight fit between the tube and the tube sheet. Re-rolling, on the other hand, involves the use of a tube rolling machine to compress the tube against the tube sheet, creating a secure and leak-proof joint.

Tube re-rolling is an immediate solution for arresting leaks from a tube-to-tube sheet joint during maintenance shutdowns if leaks are found during pressure testing. ALMUZAIN has a team of experienced technicians and specialized equipment to provide high-quality tube expansion and re-rolling services for industrial clients.

ALMUZAIN's tube expansion and re-rolling services include:

- Inspection and assessment: ALMUZAIN's team conducts a comprehensive inspection and assessment of the equipment to identify any areas of wear, damage, or corrosion that require tube expansion or re-rolling.

- Tube expansion or re-rolling: ALMUZAIN uses specialized equipment and techniques to perform tube expansion or re-rolling, ensuring a secure and leak-proof joint between the tube and tube sheet.

- Quality control: ALMUZAIN conducts rigorous quality control checks to ensure that the repair meets the client's specifications and performs as expected.

Trusted partner to leading Oil,

Gas and Petrochemical Industries.

LEADING INDUSTRIAL SERVICE PROVIDER

IN THE KINGDOM OF SAUDI ARABIA

Partners